Other

The product of the supplier has CE certificate, the supplier has ISO13485 certificate. The supplier has 28 years experience of designing and manufacturing sterilizers, the CE standard EO sterilizer which the supplier provides is the most advanced one among domestic similar products.

With more than ten years of development, VITAIMED has established good cooperation relationship with global medical partners, providing high-quality medical products and services for global medical partners.

Product Features

Standards of manufacture and sizes

EO sterilizer is designed, manufactured and verified complying with follow standards:

Standards of manufacture: European standard EN1422;

Inner size of the sterilizer

6m3: length 2.80m, width 1.35m, height 1.70m, actual volume 6.43m3.

15m3: length 6.75m, width 1.35m, height 1.70m, actual volume 15.49m3.

20m3: length 9.00m, width 1.35m, height 1.70m, actual volume 20.66m3.

Features

1. Reliability of the main components: The main components (SCADA software, industrial computer, vacuum pump,

circulation pump, air compressor, cylinder, chamber seal system, temperature/humidity/pressure sensors) can run at

least 500 circles of sterilization as normal.

2. Automatically opening and closing. Range of pressure: -80Kpa to +80Kpa; the working voltage is 3-phase 380V±10%,

frequency 50Hz.

If the voltage and frequency of the user’s place are different from China, the user takes care of converter.

3. Material: SUS304 stainless steel inside, 430 stainless steel wire-drawing board outside,

channel steel (carbon steel) for water jacket, carbon steel for door seal flange; the triangle steel on the doors,

water tank, drain bucket, vaporizer and all the pipes of the sterilizer which contact with EO gas and steam, use stainless steel.

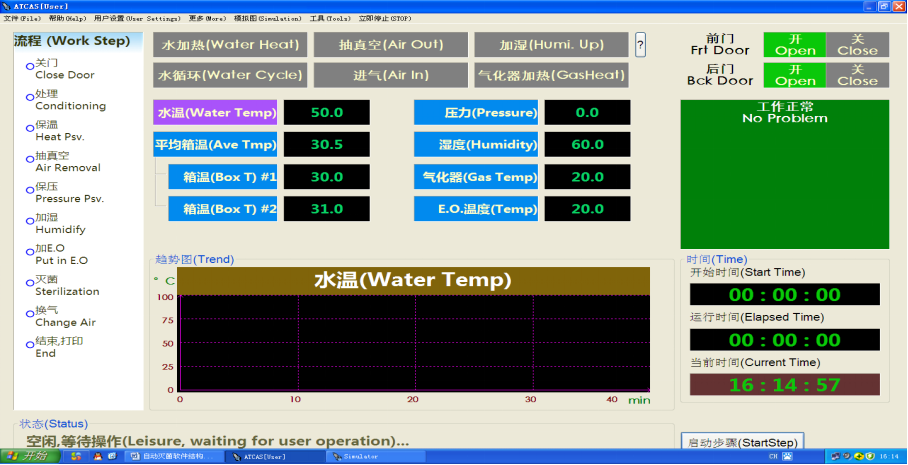

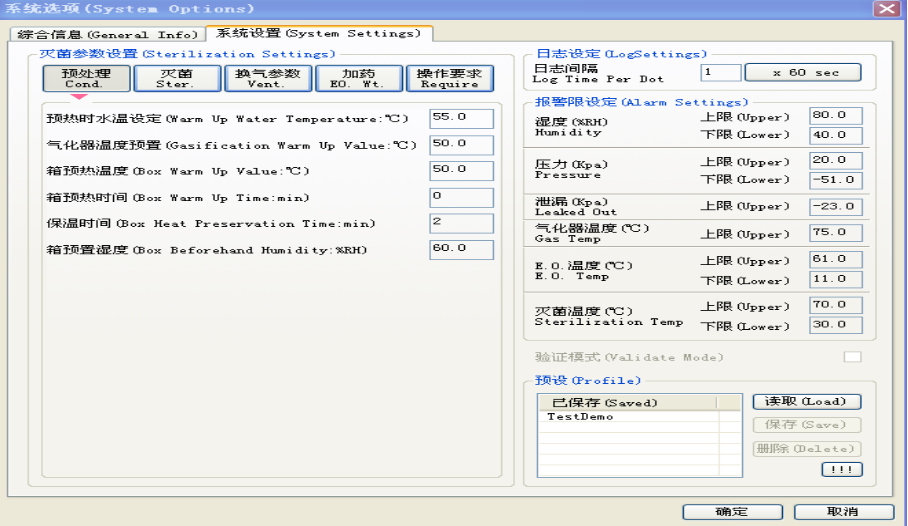

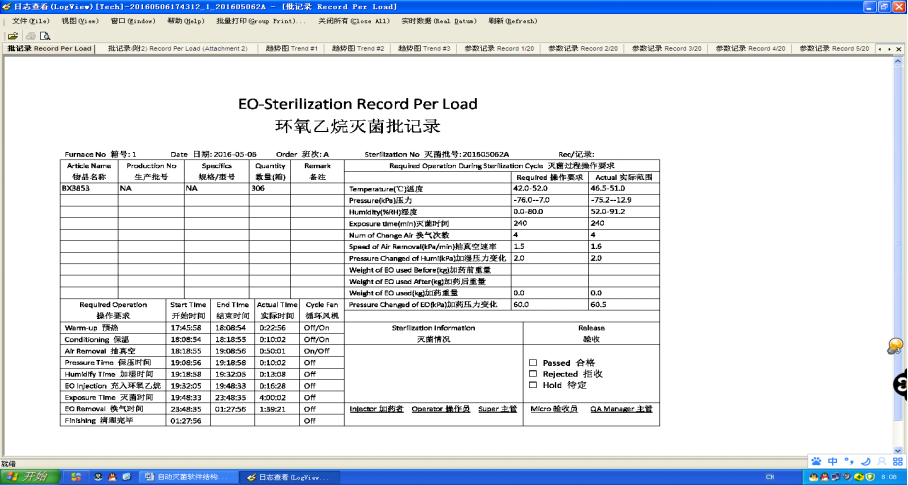

4. Control system: automatic control by industrial control computer and PLC. The parameters can be recorded, stored,

exported and printed.All the documents of the computer interface are both Chinese and English.

5. The user takes care of loading tools and validation of sterilization.

Main Specification

Main Configuration

Door control and door lock:

.The sterilizer has double slide doors which are controlled by software for open, close and lock。

.The doors would be locked and can’t be open when EO gas inside chamber;the doors can’t be closed under maintenance.

. Function of power failure protection helps the door sealers keep pressure under the circumstance of power failure to avoid EO gas leakage.

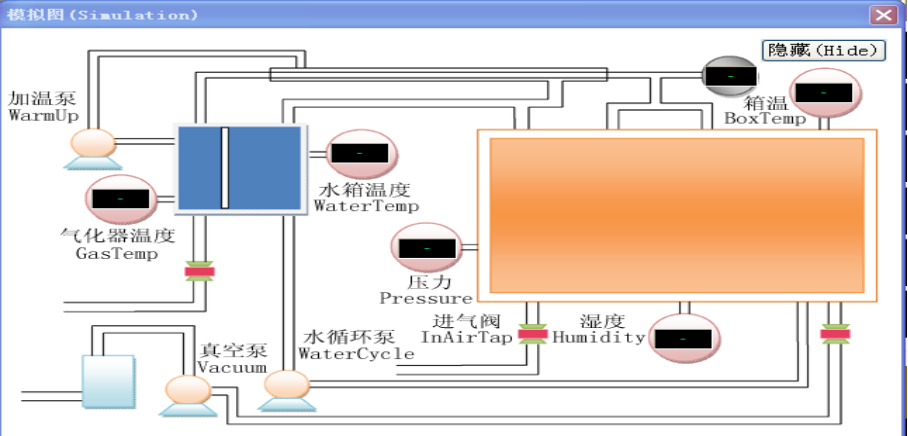

Heating and circulation system:

.It is composed of water tank, cycle pump, pipes and valves。

.We would test the water jacket by water of 0.4Mpa pressure, make sure there is no shape change or water leakage.

Vacuum system:

.It is composed of vacuum pump, pipes and valves. The vacuum system is designed to vacuum the chamber to set pressure

in set time and to flush the EO gas inside chamber.

Humidifier system:

.It is composed of automatic steam generator, pipes and valves. It is used to adjust the humidity inside chamber to make sure

product is effectively sterilized. The humidifier system is automatically working during sterilize cycle.

EO injection and Vaporizer:

.Our unique vaporizer can accurately control the EO gas temperature when inject into chamber, make sure EO was fully gasified.

Monitor and control system:

.Our computer control system is designed and produced by ourselves, based on WIN7 OS, with friendly interface it is easy to use.

The software has Chinese and English language.

. We use enough numbers of sensors which EN1422 and ISO11135 requires. The system can monitor and control the parameter

automatically, meanwhile it can on-time read, control, record, save and print the sterilize parameter and trends, the data can

be saved for at least 10 years.

. The system has power failure protection which can resume the data after power is restored. There is another data collection

and display system which is separated from the control system to make sure the sterilizer can work correctly if the computer

control system was failure.

. The software would alert when parameter was over range or there was safety risk.

. It is fully fulfilling the requirement of EN1422:2014 and ISO11135:2014.

. The control system has emergency stop knob, when the knob is pressed, the sterilizer would stop, but the control system remain power on.

.The system has three levels of authority, different user can register different user name and password, with different authority.

The software would also record all the operation by users, and custom can check the operations when necessary.

. The system can be switched between automatically control and manually Control

Waste gas treatment system:

.The EO gas was pull out by vacuum pump and then goes into waste water barrel for mixture, the EO gas will dissolve into water and

then goes into waste water ditch, after neutralization and dilution the waste water can be discharged.

+86 139 1863 8349

+86 21 5839 9546

+86 21 5839 9546

HQ Add.: Room 1601 Haibo Bldg.| No.101 Nanmatou Road | Pudong New District Shanghai 200125 China

Manufacturing Facility Add.: No.26 Huashan Middle Road, Changzhou, Jiangsu Province 213022 China

Navigation